|

|

|

Technological lines for the food, cosmetic, pharmaceutical and chemical industries. |

|

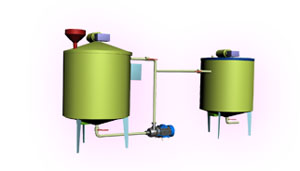

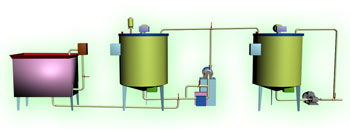

The line for the production of butter and margarine.

The line: 1 - melter blocks of fat, 2 - reactor - mixer, 3 - accumulating capacity, 4 - volume - an emulsifier, 5 - homogenizer, 6 - a rotary pump, 7 - masloobrazovatel, 8 - refrigerator. |

|

|

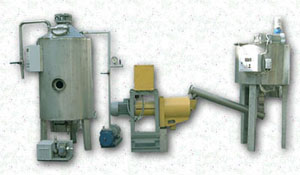

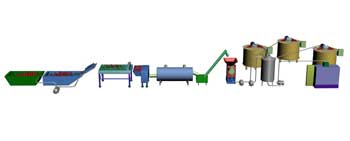

Production line podvarok, jams, fillings, jams

The line:

- Tables for sorting and bulkheads

- Washing machine

- The boiler with mixing device

- Rubbing Machine

-vacuum evaporator

- Screw conveyor

- The pump |

|

|

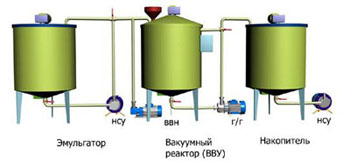

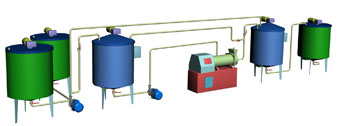

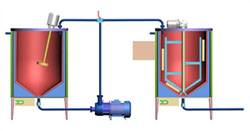

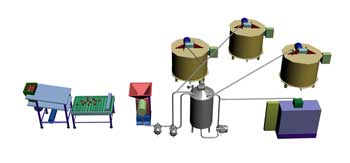

Vacuum line for production of mayonnaise

The line

- Emulsifier

- The vacuum reactor

- Drive

- Vacuum pump

- Homogenizer

- Self-priming pump

|

|

| |

Line (Set) hydrodynamic extraction from plant material

The line:

- loading capacity with a specially designed jacket teploobmennnoy

- Multi-stage rotary cavitation homogenizer special design,

- Capacity of reception with propeller stirrer

- Pipes, valves and control panel.

|

|

| |

Production line of cosmetics

The line:

- Capacity (for the preparation of pigments) with anchor stirrers and high-speed gomogenizaruyuschey

- Capacity (to melt and prepare the ground) with an anchor stirrer

- Vacuum reactor with anchor stirrer

- Capacity of funded with an anchor stirrer and heat exchange jacket

- Piping and valving

- Remote control

- Gear pump

|

|

| |

Production line of condensed milk by TU number 1

Purpose:

The production of condensed milk to TU (from dry milk and animal fat or vegetable origin) |

|

| |

Production line of condensed milk by TU number 2

Purpose:

The production of condensed milk to TU (from dry milk and animal fat or vegetable origin) |

|

| |

Production line of condensed milk by TU number 3

The line:

- Melter ARZH NP

- reactor - homogenizer

- pump NSU

- valves and

pipes with hopper,

- remote control |

|

| |

Line (Set) dispersion of carbon.

The line:

- dissolvers

- Reactor

- Homogenizer

- Scales on a curbstone

- Remote control

The actuator is made in

explosion-proof design.

|

|

| |

The line of chocolate icing.

The line:

- Installation of the production of chocolate glaze

- Aggregate rapid melting of fat.

- Transporter of bulk solids.

- Set the cooling fluid

- Tempering machines

- Pump priming NSO-3.

- Screw pump NSH.

- Semi-automatic dispenser of cocoa butter.

- A collection of glaze (2000l)

- Mold-kroshkoobrazovatel glaze.

- Pipes with heating and valving

- Homogenizer 7,5.

- Ball mill

|

|

| |

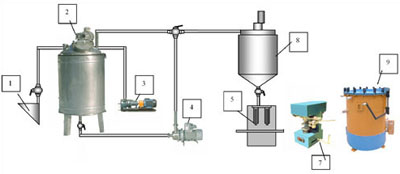

Line preparation of canned fruits, tomato paste, sauces and ketchup.

The line

1. Hopper, 2 Vacuum - evaporator, pump 3.Vakuum BBH 4. Homogenizer, 5. Dispenser - Semi -2400 Dose II, 7. Closing (seaming) machine W-5, 8. Storage tank, 9. autoclave electric |

|

| |

Versatile line for preparation of various sauces with chunks of vegetables (ketchup, jam, marmalade and jam)

The line : 1.Vakuum - the device, 2. Capacity emulsifier, 3. Siropovarochny boiler 4. Storage tank 5. Homogenizer, 6. Pump screw, 7. Hopper. |

|

| |

Line production of kvass kvass wort concentrate by fermentation

Purpose: This line is designed for making kvass kvass wort concentrate from the method of fermentation.

The line: Cooking pot siropovarochny pot fermenter, blend tank

|

|

| |

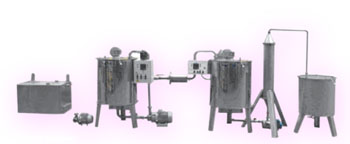

The line for the preparation of sterile ointment (cream).

The line: melting pot (Mixer) multilayer, with heating elements or steam-jacketed, with multiblade stirrer with TEN scraper, lift lid of the boiler, the control panel. |

|

| |

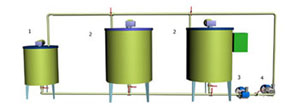

Universal production line of sauces, tomato pastes, jams

The line:

1. Смеситель-реактор,

2. Емкости для смеси,

3. Насос для вязких продуктов,

4. Гомогенизатор |

|

| |

Production line of brine

The line:

- Reactor (2 units).

- Homogenizer

- Circulation pump

- Tank

- Heat exchanger

- Remote control

- Chiller |

|

| |

Line production of tomato paste

The line:

Washer

Wiping the machine

vacuum apparatus

Homogenizer

Storage tank

|

|

| |

Line (installation) for the production of jam, mayonnaise, ketchup, condensed milk and boiled

Principle of operation. Prepared mashed potatoes loaded into the hopper, and by means of vacuum in the vacuum apparatus is loaded into it further through the hatch can be made optional components (sugar, etc).

|

|

| |

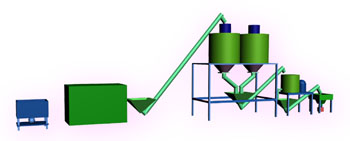

Production line of mixes

The line:

1-cone receiver, 2-metering of cement, 3 - support metering of cement, 4 - pellet dispenser, 5 - support metering granules, 6 - conveyor belt with a grooved flooring 7 - conveyor belt inclined, 8 - node handout, 9 - drum mixer, 10 - bunker, 11 - bearing, 12 - geared motor on the frame, 13 - a mobile platform, 14 - frequency converter, 15 - automatic switch |

|

|

Composition line

- Mixer

- disperser

- Drive

- tap

|

|

| |

Состав линии

|

|

| |

Line mixing epoxy resin with quartz sand

Composition line:

- Mixer (vertical)

- Dispenser

- Vacuum pump |

|

| |

Line for production of household chemical products

Composition line:

• Reactor

• Reservoir

• Reservoir

• The pump for viscous products

• Homogenizer

• Semi-dispenser

• piping and

armature

• Remote Control |

|

|

The line of well cement

Structure line:

- mixers of various types

- screening plants (sieve)

- packaging machines

- dispensers

- raspakovochnye device

- dryer

- bins

|

|

| |

Line blending (Blended capacity)

Blended containers used for fast

mixing two or more component liquids.

The lines used in the production of wine and wine drinks, etc. |

|

| |

Line recovery of juice

Composition line:

- The capacity of water treatment

- Reactor

- Homogenizer

- Pump NSU

- Storage tank

- Heat exchanger

- Buffer tank |

|

| |

Production line of chocolate-coated semi

The line:

-rastopitel fat (zhirotopka),

reactor,

-homogenizer

tempeiruyuschaya-capacity,

-gear pump,

-pump for viscous products.

|

|

| |

Production lines of canned milk

The line:

1. Siropovarochny

boiler mixer.

2. crystallizer

-cooler.

3. homogenizer

4. Remote control. |

|

| |

The line:

- Receiving hopper

- Inspecting conveyor

- An intermediate bunker

- Crusher

- Wiping the machine

- Gear pump

- Capacity of a small intermediate

- Packaging machine

- Table for packing

- Sterilizing jars

- Beading machine

- Sterilizing products

- Installation of a vacuum-evaporation (capacity with a stirrer and heating elements, a homogenizer, a vacuum pump)

|

|

| |

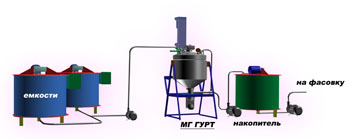

Production line of mustard (MG Gurt)

The line:

- Tanks

- Install MG Gurt

- Storage tank |

|

| |

Universal line for the production of homogeneous mixtures

The line:

- Emulgatsionnaya capacity

- Capacity of water

- Reactor

- Homogenizer

- Gearmotor reactor

- TEN reactor |

|

| |

Line production of tomato paste with the installation MG Gurt

The line:

- capacity,

- Installation of MG Gurt,

- Drive,

- Drag the heat exchanger,

- Dispenser,

- Pumps |

|

| |

Production line of mustard with the installation VMG Corum

The line:

- setting VMG Corum

- Storage tank

- Pumps

- Dispenser |

|

| |

Plant (line) production of emulsifiers, preservatives, lubricants and grease

The line (see below) |

|

| |

Линия смешивания сухих пищевых добавок.

The line (see below) |

|

| |

Production line of dietary and nutritional therapy

The line:

- two wash tubs with grids

- top

- reactor pasteurizer with a homogenizer

- cumulative capacity

- packaging unit

- tank mixing a concentrate of marine

algae with juice

- cumulative capacity to pump

- pasteurization unit

|

|

| |

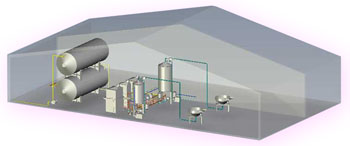

Line production of milk fat

Sostavav line production of milk fat:

fat melter with buffer

plate heat exchanger

weight capacity

grease reactor digester - 2 pcs.

buffer tank with a filter

buffer capacity at tenzooporah

filter - 2 pcs.

pump impeller

screw pump

control cabinet

stop aramatura and pipes

|

|

| |

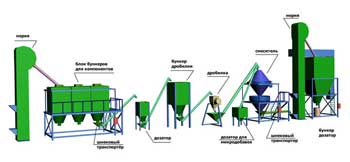

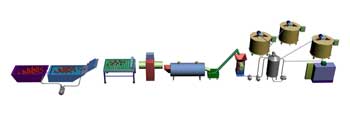

The line feed production

Included Parts Equipment:

Noria -2 units

Block bins for components

Screw feeder

dispenser

Crusher hopper

Crusher

Dispenser microadditives

Mixer dvuhkonusny

dispenser |

|

| |

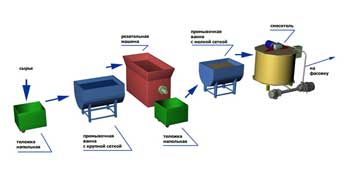

Production line of gel cosmetics

Composition of the line:

- bath wash - 2 pcs

- cutter

- mixer

- screw pump

- homogenizer

|

|

| |

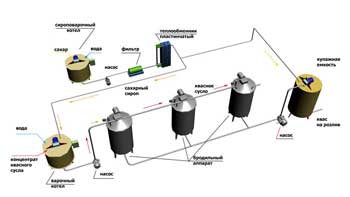

Line production of kvass concentrate

Equipment for the production of kvass concentrate:

- Siropovarochny boiler

- Filter

- Plate heat exchanger

- Digester

- Fermenter

- Blend tank |

|

| |

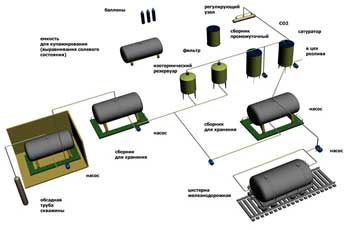

Mineral water production line

The line: capacity for blending

filter

saturator

isothermal reservoir,

gasification plant

regulatory node

collection storage |

|

| |

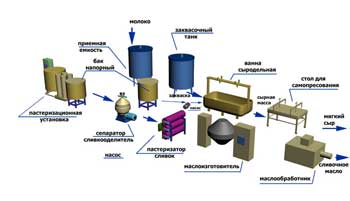

Line production of soft cheese and butter

Equipment for the production of soft cheese:

- Feeding capacity

- Starter tank

- Bathtub Cheese

- Table for samopresovaniya |

Equipment for the production of butter:

- Pasteurization plant

- Separator cream separator

- Pasteurizer cream

- Masloizgotovitel

- Masloobrabotnik |

|

|

| |

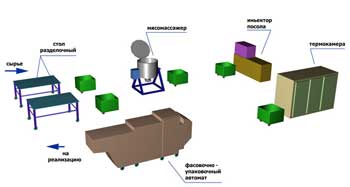

Production line of gourmet meat products

The line:

cutting tables

myasomassazher

injector salted

truck interior

heat chamber

packaging machine |

|

| |

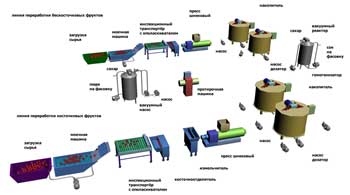

Production line of juice and puree

The line:

- Bin boot

- Machine wash

- Inspection conveyors

rinse with

- Kostochkootdelitel

- Shredders

- Screw press

- Pumps

- Drive

- Rubbing Machine

- Vacuum Reactors

- Homogenizers |

|

| |

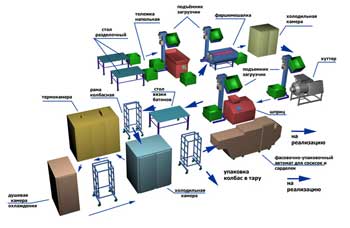

Production line of hot dogs, wieners, sausages

The line:

Cutting tables

top

mixers

picker

trolley floor

refrigerators

Cutter |

syringe sausage

table for knitting sticks

heat chamber

frame sausage

packaging machine

|

|

|

| |

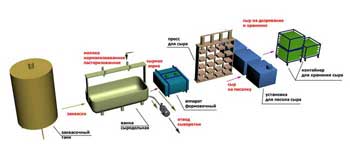

Production line of cheese

Equipment for the production of cheese.

1. starter tank la cheese

2. Bath Cheese.

3. Molding apparatus for the production of cheese.

4. Press cheese

5.Ustanovka for salting of cheese.

6. A container for storing cheese |

|

| |

Production line of spreads

The line:

- Melter of fat (2 items)

- The capacity for making

butter-fat emulsion

- Homogenizer

- Bath pasteurisation

- The pump plunger

- Masloobrazovatel-mold |

|

| |

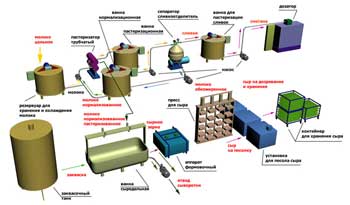

Production line of cheese and sour cream

The line for the production of sour cream

1. Storage tank and cooling of milk

2. Tubular pasteurizer

3.

Bath normalization

4. Bath pasteurization

5. Separator - cream separator

6. Bath pasteurization

7. Dispenser |

The line for the production of cheese.

1. starter tank la cheese

2. Bath Cheese.

3. Molding apparatus for the production of cheese.

4. Press cheese

5.Ustanovka for salting of cheese.

6. A container for storing cheese

|

|

|

| |

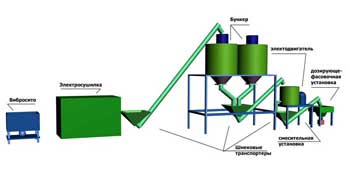

Production line of mixes

Equipment Package:

- Vibrating

- Elektrosushilka

- Screw trasporter

- Bunker

- Mixing plant

- Filling doziruyusche-setting

- Remote control |

|

| |

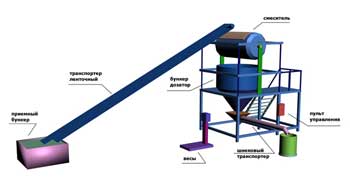

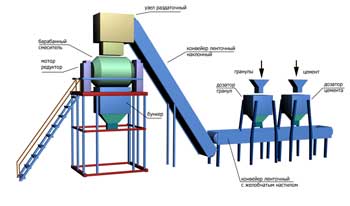

Production line of mixes with drum mixer

Equipment Package

- Hopper,

- Conveyor belt,

- Drum mixer,

- Screw conveyor,

- Remote control |

|

| |

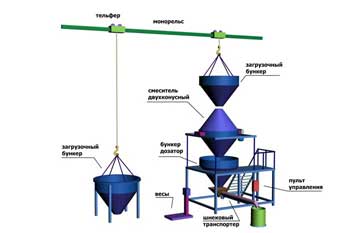

Production line of mortar mixer with dvuhkonusnym

The line:

- Hopper

- Mixer dvuhkonusny

- Hopper feeder

- Screw conveyor

- Hoist

- Monorail

- Remote control |

|

| |

Line processing of stone fruit in jam and jelly (plum, apricot, peach, etc.)

The line :hopper, washer, inspection conveyor with opolaskmvatelem, kostochkootdelitel, blancher, screw conveyor, Rubbing machines, storage, vacuum pump, vacuum evaporation plant, homogenizer, filling and dispensing machine. |

|

| |

Seedless fruit processing line for jam and jelly (Grushovaya, apple, quince, etc.)

The line: hopper, washer, inspection conveyor with opolaskmvatelem, chopper, blancher, screw feeder, Rubbing machines, storage, vacuum pump, vacuum evaporation plant, homogenizer, filling and dispensing machine |

|

| |

Line processing of berries for jam and jelly (strawberry, raspberry, currant, etc.)

The line: hopper, washing - shake machine, inspection conveyor with opolaskmvatelem, Rubbing machines, storage, filling and dispensing machine. |

|

| |

Production line of minced

The line

cutting tables

top

mixers

packaging machine lift-dump

truck floor. |

|

| |

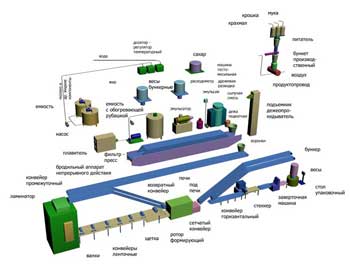

Production line of cookies, krekera

|

|

| |

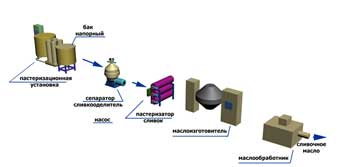

Butter production line

composition line

- pasteurization plant

- Separator cream separator

- Pasteurizer cream

- Masloizgotovitel

- Masloobrabotnik |

|

| |

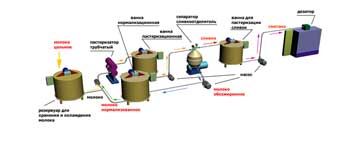

Cream production line

The line

1. Storage tank and cooling of milk

2. Tubular pasteurizer for the production of sour cream

3. Bath normalization for the production of sour cream

4. Pasteurization bath for the production of sour cream

5. Separator - cream separator

6. Bath pasteurized cream

7. Dispenser

|  |

| |

The line of oil-well cement

The line

cone-receiving,

The metering of cement,

- Support metering of cement,

- Pellet dispenser,

- Support metering granules

- Conveyor belt with a grooved flooring,

- Conveyor belt inclined,

|

- Node handout,

- Drum mixer

- Bunker,

-reliance,

- Geared motor on the frame,

- A mobile platform,

-frequency converter

automatic switch-

|

|

|

| |

|

|